Supply chain disruption has become a long-term reality for galleries, retailers, designers, photographers, and other businesses that depend on reliable production timelines. When frames are made and sourced domestically, framing mitigates supply chain risk by improving predictability, quality control, and turnaround times.

US-made framing provides greater stability in an environment shaped by shipping delays, rising costs, and global uncertainty. Below are three ways domestic framing helps professional partners plan more confidently.

1. Domestic Framing Reduces Lead Time Volatility

One of the most immediate ways framing mitigates supply chain risk is by shortening and stabilizing lead times. International sourcing introduces variables that are difficult to control — port congestion, customs delays, container shortages, and extended transit windows.

With US-made framing, our clients benefit from:

- Shorter production-to-delivery timelines

- Fewer logistics handoffs

- Greater reliability during peak demand or rush orders

For businesses managing installations, retail rollouts, or multi-location projects, predictable timelines reduce downstream risk and protect customer commitments, all while streamlining your framing process.

“Frame It Easy is incredibly vital to this exhibition; it cannot be understated.”

Jack, Exhibitions Assistant at the Alliance for Young Artists and Writers

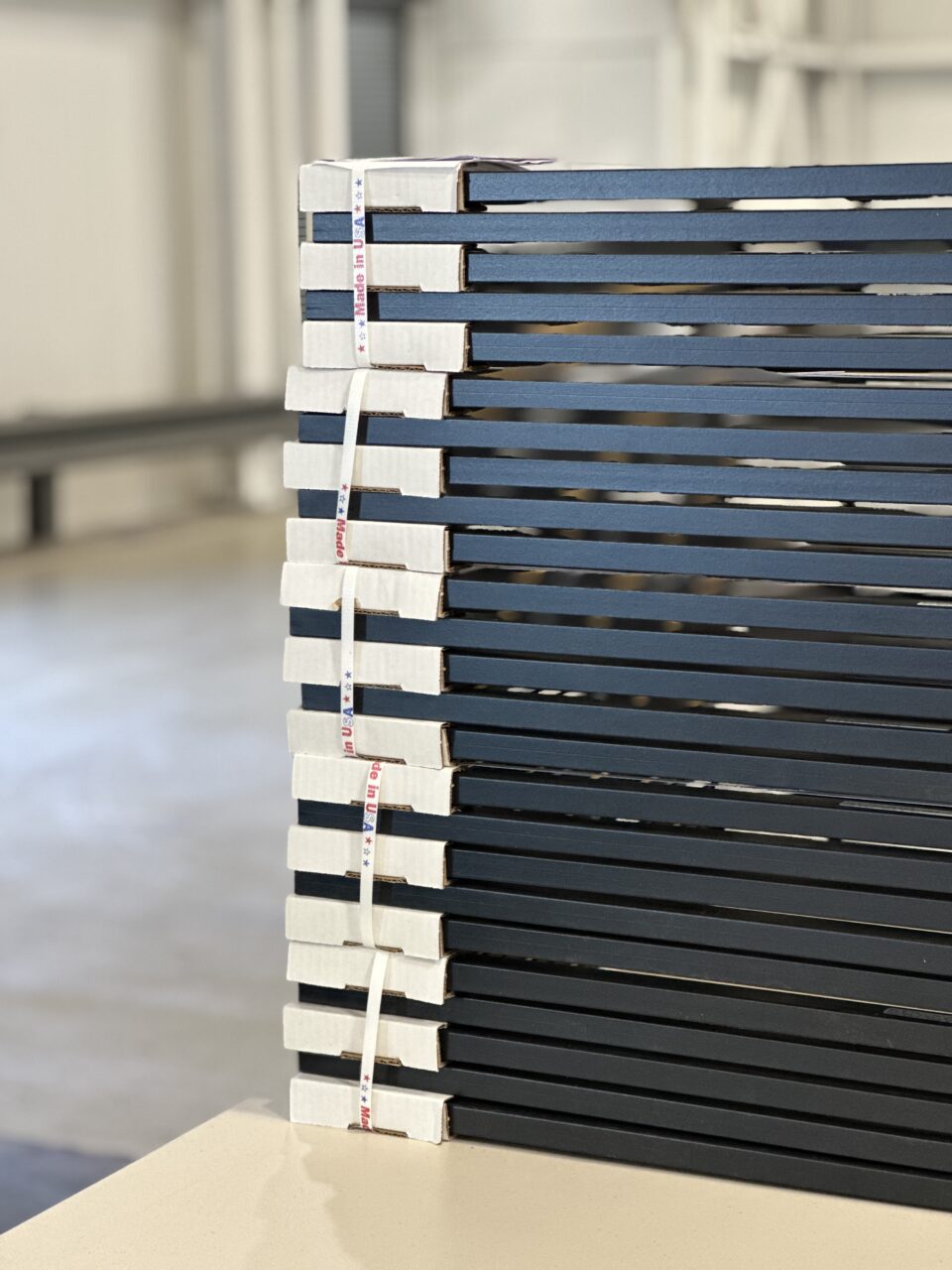

2. US-Made Framing Improves Quality Control and Consistency

Supply chain risk isn’t only about delays — it’s also about inconsistent quality. Overseas manufacturing often limits visibility into framing materials, tolerances, and production standards.

Domestic framing allows for:

- Closer oversight of materials and finishes

- Consistent specifications across repeat orders

- Faster issue resolution if adjustments are needed

When framing mitigates supply chain risk at the quality level, clients experience fewer returns, less rework, and more confidence scaling their programs.

3. Domestic Sourcing Creates Pricing and Planning Stability

Global supply chains are vulnerable to fluctuating freight costs, tariffs, and currency shifts. These variables can disrupt budgets and erode margins with little warning.

US-made framing helps mitigate those risks by offering:

- More predictable pricing structures, as well as bulk pricing

- Reduced exposure to international cost swings

- Stronger supplier accountability and communication

For buyers working within fixed contracts or long-term agreements, this stability makes planning easier and outcomes more reliable.

Why Framing Mitigates Supply Chain Risk for Framing Partners

Choosing domestic framing is not just an operational decision — it’s a strategic one. When framing mitigates supply chain risk, businesses gain:

- Faster turnaround times

- Consistent quality at scale

- Greater confidence in delivery and execution

In a market where reliability is a competitive advantage, US-made framing supports stronger partnerships and more resilient operations.

Who This Is For

This approach to framing is designed for professionals who depend on reliable timelines, consistent quality, and predictable outcomes. It’s especially relevant for:

- Galleries and retailers managing repeat orders or seasonal displays

- Interior designers and design firms coordinating client installations

- Photographers and artists producing work at scale or on deadline

- Corporate teams sourcing framed artwork for offices, corporate events, or multiple locations

- Print partners and creative businesses integrating framing into their offerings

If your work requires frames to arrive on time, look consistent from order to order, and meet professional standards, domestic framing helps reduce risk at every stage.

What This Means for Your Team

Choosing framing that mitigates supply chain risk doesn’t just improve logistics — it simplifies how your team works day to day.

- More predictable timelines make it easier to plan projects and meet deadlines

- Fewer surprises, with consistent materials and finishes across orders

- Less rework and fewer delays, reducing internal back-and-forth

- Greater confidence when scaling, whether you’re ordering one frame or one hundred

In short, domestic framing supports smoother workflows, clearer expectations, and stronger delivery — so your team can focus on the work, not the uncertainty.

Real projects, real results.

Explore how our framing solutions supported a large-scale, professional program in our Scholastic Art & Writing Awards feature.

Key Takeaway for Our Business Clients

How does framing mitigate supply chain risk?

Framing mitigates supply chain risk by reducing reliance on overseas manufacturing, shortening lead times, and improving quality control. When frames are made domestically, businesses experience fewer delays, more consistent materials, and more predictable delivery schedules.

Why does US-made framing reduce supply chain disruption?

US-made framing reduces supply chain disruption by avoiding international shipping delays, tariffs, and port congestion. Domestic sourcing allows for faster production, clearer communication, and greater pricing stability.

Who benefits most from framing that mitigates supply chain risk?

Any business that depends on reliable timelines and consistent quality — including galleries, retailers, designers, photographers, corporate teams, and print partners — benefits from framing that mitigates supply chain risk.

Looking for a more reliable framing partner?

Our US-made framing solutions are built to support recurring orders, tight timelines, and professional standards.

Create a Business Account to get started.